When it comes to constructing or renovating a space, the ceilings grid hanger wire is an essential component often overlooked. Whether you’re working on a residential, commercial, or industrial project, understanding the role and functionality of ceiling grid hanger wires is crucial. This article will provide a comprehensive overview of ceiling grid hanger wire, including its features, benefits, installation methods, and tips for ensuring optimal performance.

What is Ceiling Grid Hanger Wire?

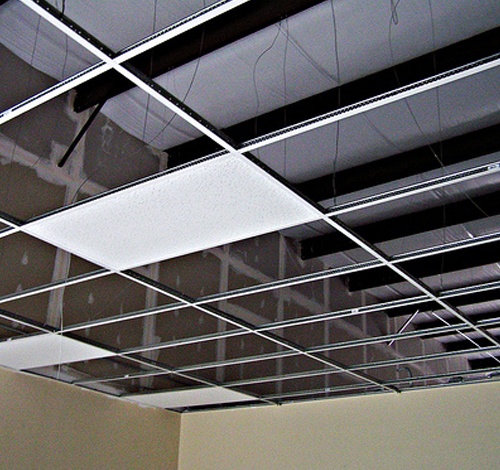

Ceiling grid hanger wire is a crucial element used to support and stabilize suspended ceiling systems. Typically made of galvanized steel or stainless steel, this wire is designed to carry the weight of ceiling panels, lights, HVAC systems, and other components that may be installed in a suspended ceiling grid system. The use of ceiling grid hanger wire helps ensure that these elements remain secure, providing a safe and aesthetically pleasing ceiling installation.

Key Features of Ceiling Grid Hanger Wire

- Material Composition:

- Ceiling grid hanger wires are commonly made from high-strength materials, primarily galvanized or stainless steel. Galvanization offers corrosion resistance, making the wire suitable for various environments, including those with high humidity or exposure to moisture.

- Different Gauge Options:

- These wires come in various gauges, which determine their strength and load-bearing capacity. Typically, a thicker gauge (lower number) can support more weight. It’s important to choose the appropriate gauge based on the specific requirements of your project.

- Flexible and Adjustable:

- Ceiling grid hanger wire is designed to be flexible, allowing for easy adjustment during installation. This flexibility enables installers to make precise adjustments to the height and level of the suspended ceiling system.

- Easy Installation:

- Installing ceiling grid hanger wires is generally straightforward, often requiring minimal tools and equipment. They can be cut to length and secured to the building structure using specialized fasteners, making them a convenient choice for contractors and DIY enthusiasts alike.

- Compatibility with Various Systems:

- Ceiling grid hanger wires are compatible with different ceiling grid systems, including T-bar grids, drywall ceilings, and acoustic ceiling tiles. This versatility makes them a go-to solution for various applications.

Read too: Discovering the Charm of Nautical Outdoor Ceiling Fans for Your Coastal Retreat: Sail into Style

Benefits of Using Ceiling Grid Hanger Wire

1. Enhanced Stability and Safety

One of the primary benefits of using ceiling grid hanger wire is the enhanced stability it provides to suspended ceiling systems. By securing the ceiling panels and other elements, the wire helps prevent sagging, shifting, or collapse, ensuring safety in the workspace.

2. Cost-Effective Solution

Compared to other ceiling support systems, using ceiling grid hanger wire can be a cost-effective solution. The materials are generally inexpensive, and the ease of installation can save both time and labor costs during construction or renovation.

3. Versatile Applications

Ceiling grid hanger wire can be used in a wide variety of settings, from commercial offices to industrial warehouses. This versatility allows contractors to utilize the same product across different projects, simplifying inventory and reducing costs.

4. Aesthetic Appeal

A well-installed suspended ceiling can enhance the aesthetic appeal of a space. Ceiling grid hanger wire contributes to a clean, professional look, helping to create a polished finish in any environment.

5. Fire Safety Compliance

Many ceiling grid systems are designed to meet fire safety codes. Using quality ceiling grid hanger wire helps ensure that the entire ceiling assembly complies with relevant regulations, providing peace of mind for building owners and occupants.

Installation Process for Ceiling Grid Hanger Wire

Tools and Materials Needed

Before starting the installation, gather the necessary tools and materials:

- Ceiling grid hanger wire (appropriate gauge)

- Wire cutters

- Pliers

- Measuring tape

- Level

- Ceiling anchors or fasteners

- Drill (if needed for anchors)

Step-by-Step Installation Guide

Step 1: Plan the Layout

Begin by planning the layout of your ceiling grid system. Measure the dimensions of the room and mark the locations for the main runners, cross tees, and any other components you’ll be installing.

Step 2: Determine Hanger Wire Spacing

Ceiling grid hanger wires should typically be spaced no more than 4 feet apart, but local building codes may vary. Check your local codes for specific requirements and adjust your plan accordingly.

Step 3: Attach Hanger Wires to the Structure

Using a drill or hammer, attach the ceiling grid hanger wires to the overhead structure. This may involve securing them to ceiling joists, beams, or existing structural elements. Ensure that the hangers are securely fastened and can support the weight of the ceiling grid.

Step 4: Cut and Install the Hanger Wire

Using wire cutters, cut the hanger wire to the desired length. Make sure to leave some extra length for adjustments. Attach one end of the wire to the ceiling grid, ensuring it’s secure.

Step 5: Adjust Height and Level

Once the wires are attached, adjust the height of the ceiling grid by pulling on the hanger wires as needed. Use a level to ensure that the grid is perfectly horizontal.

Step 6: Secure the Grid System

After leveling the grid, secure all components, including main runners and cross tees, to the hanger wires. Ensure all connections are tight and stable.

Safety Precautions

- Always wear safety goggles when cutting or working with wire to protect your eyes from flying debris.

- Ensure the workspace is clear of obstacles to prevent tripping or falling.

- Double-check all connections and fasteners to ensure everything is secure before adding any load to the ceiling grid system.

Maintenance Tips for Ceiling Grid Hanger Wire

Proper maintenance of your ceiling grid hanger wire system will ensure its longevity and performance. Here are some essential maintenance tips:

1. Regular Inspections

Periodically inspect the ceiling grid and hanger wire for any signs of wear, corrosion, or damage. Check for loose connections and re-secure any components as necessary.

2. Keep it Clean

Dust and debris can accumulate on ceiling grids, affecting their appearance and functionality. Regularly clean the ceiling and surrounding areas to maintain a tidy space.

3. Monitor Load Capacity

Be mindful of the load capacity of your ceiling grid system. Avoid placing heavy objects on or above the ceiling grid that exceed the weight limit, as this can strain the hanger wire and other components.

4. Reinforce as Needed

If you notice sagging or instability in the ceiling grid, consider adding additional hanger wires or reinforcing existing ones to provide extra support.

Common Applications for Ceiling Grid Hanger Wire

1. Commercial Spaces

In offices, retail stores, and other commercial spaces, ceiling grid hanger wire is commonly used to create suspended ceilings. This allows for easy access to plumbing, electrical wiring, and HVAC systems while maintaining a professional appearance.

2. Educational Institutions

Schools and universities often utilize ceiling grid systems in classrooms, hallways, and auditoriums. The use of hanger wire helps ensure that ceiling tiles are securely in place, contributing to a safe and comfortable learning environment.

3. Industrial Facilities

In industrial settings, suspended ceilings are frequently used to conceal mechanical systems and provide a clean look. Ceiling grid hanger wire is essential in these applications to support heavy lighting fixtures and HVAC equipment.

4. Residential Homes

Many homeowners opt for suspended ceilings in basements, living rooms, and other areas to improve aesthetics and functionality. Ceiling grid hanger wire plays a vital role in ensuring the stability and safety of these installations.

Conclusion

Understanding the importance of ceilings grid hanger wire is crucial for anyone involved in construction or renovation projects. From its ability to provide enhanced stability and safety to its cost-effectiveness and versatility, this seemingly simple component plays a significant role in creating functional and attractive ceiling systems. By following proper installation techniques and maintenance practices, you can ensure that your suspended ceiling remains secure and visually appealing for years to come. Whether you are a contractor, DIY enthusiast, or homeowner, investing in quality ceiling grid hanger wire is a decision that will pay off in the long run.