When it comes to constructing stable and functional ceilings, one essential component that often goes unnoticed is 12 Gauge Ceiling Wire. In this comprehensive guide, we’ll delve into the versatility and uses of 12 Gauge Ceilings Wire in various construction projects, exploring its benefits, applications, and installation techniques.

Understanding 12 Gauge Ceiling Wire

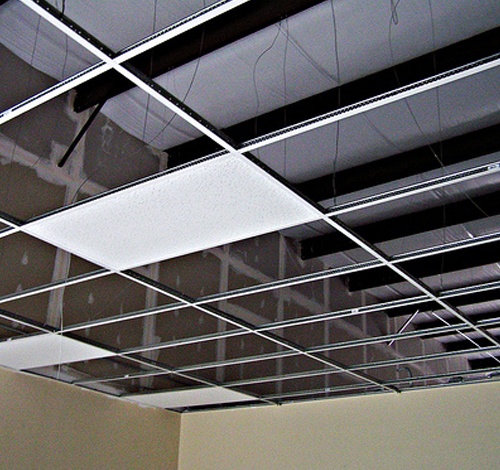

12 Gauge Ceiling Wire, also known as ceiling hanger wire or ceiling suspension wire, is a durable and flexible wire commonly used in the construction industry to support suspended ceilings. It is typically made of galvanized steel for strength and corrosion resistance, with a diameter of 0.0808 inches (2.053 mm), making it suitable for supporting heavy loads and providing stability to ceiling systems.

Benefits of 12 Gauge Ceiling Wire

- Strength and Durability: 12 Gauge Ceilings Wire is designed to withstand the weight of suspended ceilings and other building components, providing reliable support and stability. Its sturdy construction and galvanized finish make it resistant to corrosion, rust, and damage, ensuring long-lasting performance in various environmental conditions.

- Flexibility and Versatility: Despite its strength, 12 Gauge Ceiling Wire is flexible and easy to work with, allowing for quick and efficient installation in a wide range of ceiling applications. It can be bent, twisted, and shaped to fit the contours of the ceiling structure, making it suitable for both straight and curved installations.

- Compatibility with Building Codes: 12 Gauge Ceiling Wire meets industry standards and building codes for suspended ceiling installations, ensuring compliance with safety and structural requirements. It is commonly used in commercial buildings, offices, schools, hospitals, and other facilities where suspended ceilings are prevalent.

- Cost-Effectiveness: Compared to other ceiling support systems, such as threaded rods or chains, 12 Gauge Ceiling Wire is a cost-effective solution for suspending ceilings. Its affordability, combined with its strength and durability, makes it a preferred choice for contractors and builders looking to minimize project costs without compromising quality.

Applications of 12 Gauge Ceiling Wire

12 Gauge Ceiling Wire is used in a variety of construction projects and applications, including:

- Suspended Ceiling Systems: One of the primary applications of 12 Gauge Ceiling Wire is in suspended ceiling systems, where it serves as the primary support structure for ceiling tiles, light fixtures, and HVAC ductwork. It provides stability and load-bearing capacity, allowing for the installation of ceiling grids and panels.

- Acoustical Ceiling Installations: In acoustical ceiling installations, 12 Gauge Ceiling Wire is used to suspend acoustic panels and tiles from the ceiling structure. It helps absorb sound and reduce noise levels in commercial and residential spaces, improving overall comfort and acoustics.

- Lighting and Electrical Wiring: 12 Gauge Ceiling Wire can also be used to support lighting fixtures, electrical wiring, and conduit runs in ceilings. It provides a secure and stable mounting point for fixtures and wiring, ensuring safe and reliable electrical connections.

- HVAC and Mechanical Systems: In addition to supporting ceiling components, 12 Gauge Ceiling Wire is used to hang HVAC ductwork, piping, and mechanical systems from the ceiling. It helps distribute weight evenly and prevent sagging or shifting, ensuring the proper functioning of mechanical systems.

Installation Techniques and Best Practices

When installing 12 Gauge Ceiling Wire, it’s essential to follow industry best practices and safety guidelines to ensure a secure and reliable installation. Here are some tips and techniques to keep in mind:

- Proper Spacing: Space the ceiling wires evenly and according to the manufacturer’s recommendations to distribute weight evenly and prevent sagging. Use wire hangers or clips to secure the wire to the ceiling joists or structural supports.

- Secure Attachment Points: Ensure that the ceiling wires are securely anchored to the ceiling structure using appropriate fasteners, such as eye screws or ceiling anchors. Avoid overloading the wires or exceeding their weight capacity to prevent structural damage or failure.

- Use of Tools: Use wire cutters, pliers, and other appropriate tools to cut, bend, and shape the ceiling wire as needed during installation. Wear gloves and eye protection to protect against sharp edges and flying debris.

- Inspect for Damage: Before installing the ceiling wire, inspect it for any signs of damage or defects, such as kinks, bends, or corrosion. Replace any damaged wire to ensure the integrity and stability of the ceiling support system.

Conclusion

In conclusion, 12 Gauge Ceiling Wire is an essential component of suspended ceiling systems, providing strength, durability, and stability to overhead structures. Whether used in commercial buildings, offices, schools, or residential homes, this versatile wire plays a crucial role in supporting ceiling tiles, light fixtures, HVAC ductwork, and other building components. By understanding its benefits, applications, and installation techniques, contractors and builders can ensure the successful implementation of ceiling projects while maintaining compliance with industry standards and building codes.